Doggo IoT

Energy Monitoring

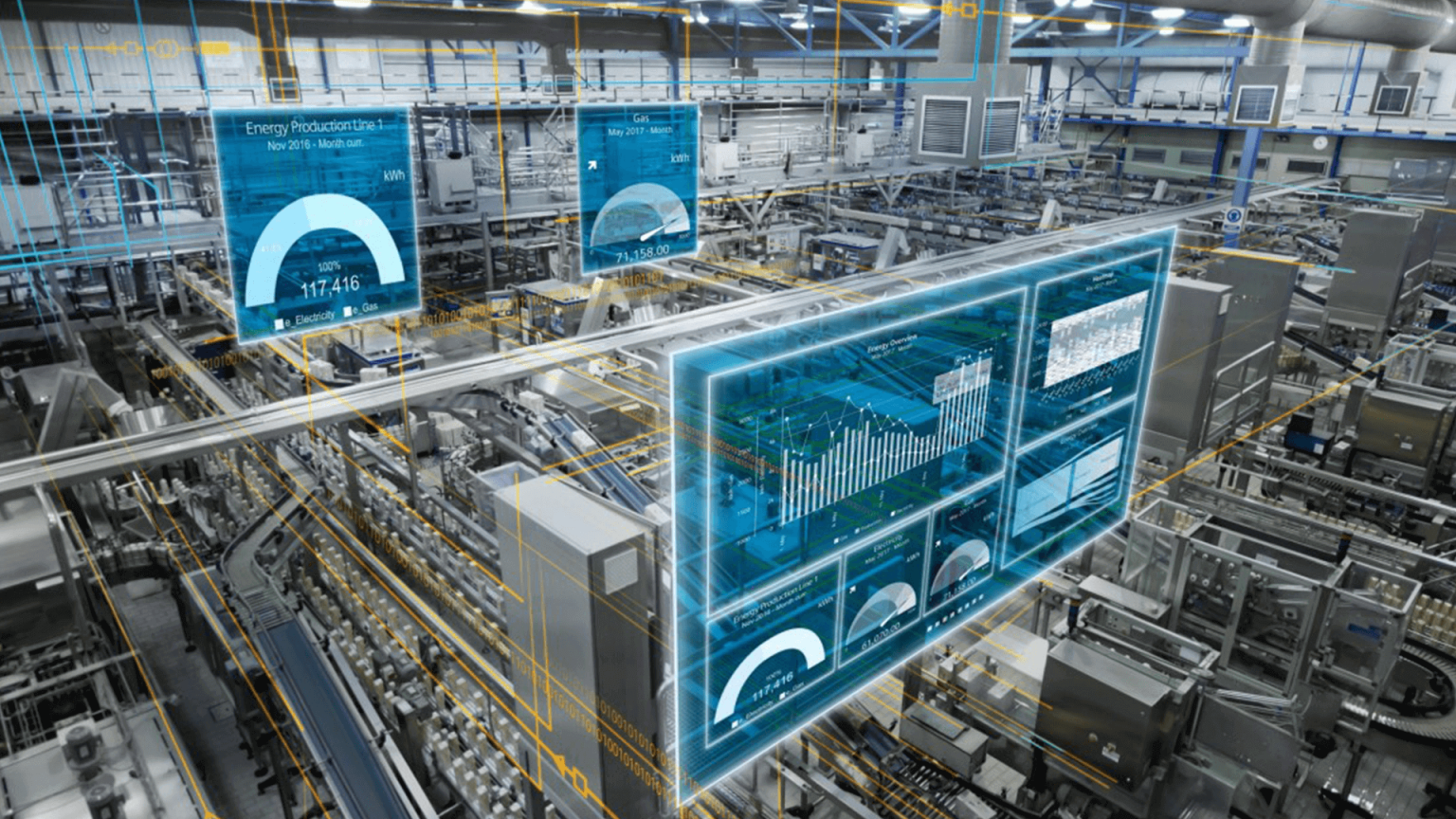

Factory energy monitoring and optimization

The Internet of Things (IoT) enables the monitoring and optimization of factory energy by using small, internet-connected sensors to detect and monitor energy usage within a factory.

These devices, also known as sensors or nodes, may be installed throughout the factory to collect data on energy use, such as power, water, and gas consumption. The data obtained by these sensors is then transmitted to a central database, where it may be analysed and visualised for a variety of purposes, including identifying high-energy consumption areas, tracking energy usage over time, and detecting opportunities for optimization.

This can lead to lower energy bills, greater energy efficiency, and a smaller carbon footprint from the factory operations. Additionally, these devices can be used for automating energy management by automatically turning off lights and equipment when not in need, adjusting heating/cooling systems as per the number of occupants or outside temperatures, and optimizing production processes to minimize power consumption.

Utilising IoT to monitor and optimize energy can help factories cost savings, reduce their environmental impact, and improve overall operational efficiency.